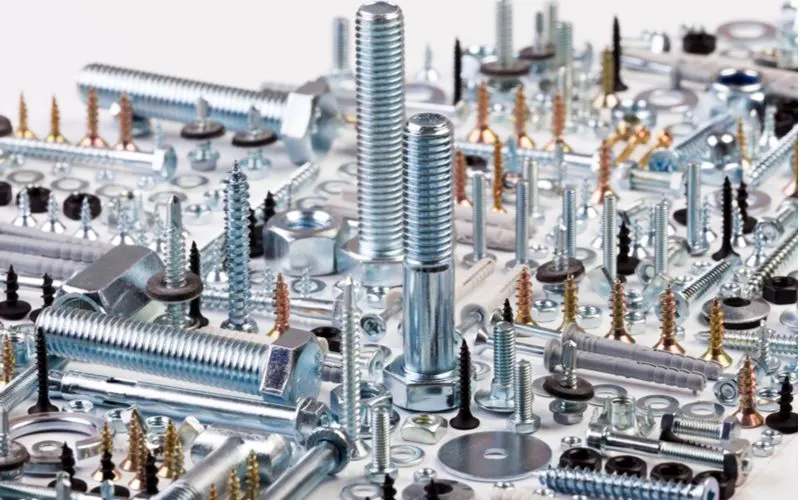

A quick glance down the hardware aisle tells you that there are many different types of screws. But what does each one do, and when should you use them? Don’t worry; we’ll cover this and more in our guide below.

Anyone can tell that screws have different sizes, but to the untrained eye, it may even seem like most screws are more or less the same type of object.

But once you know what to look for, you’ll be able to see that different types of screws have noticeably different designs that optimize them for specific situations.

What Are the Different Types of Screws?

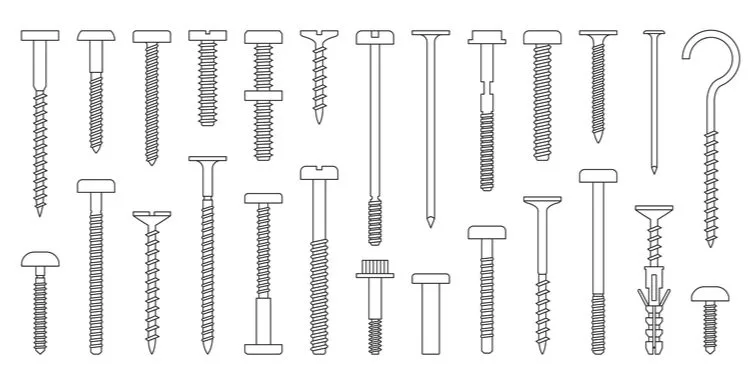

Tasha and Deki/Shutterstock

It is pretty easy to notice that screws have different sizes and thicknesses. And that makes sense, considering you have to use them in a wide range of situations.

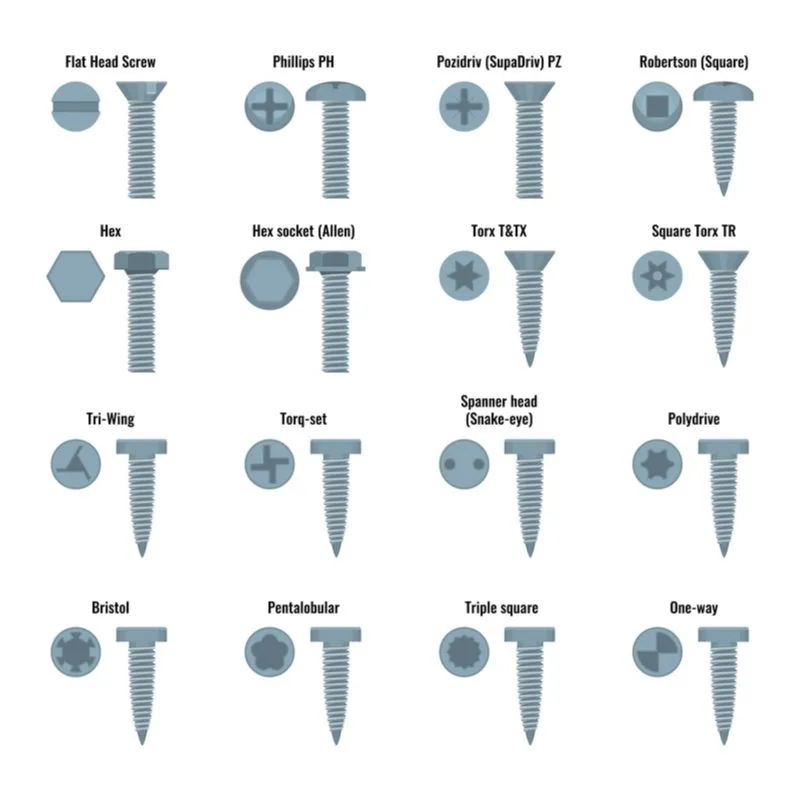

You’re also likely familiar with the different tops of the screws, flathead, and Phillip’s head.

But what you might not realize is just how intricate and subtle the differences between types of screws are.

You can separate a screw into multiple components, and it is the differences between them that determine what type of screw you have.

The main components of a screw are:

- Drive

- Head

- Shank

- Threads (including thread angle, pitch, and crest)

- Thread length

- Major diameter

- Minor diameter

- Tip

Materials such as these makeup screws:

- Aluminum

- Stainless steel

- Brass

Getting to know the anatomy of a screw via these components will make it easier to spot differences as you encounter them.

Types of Screws & When to Use Each

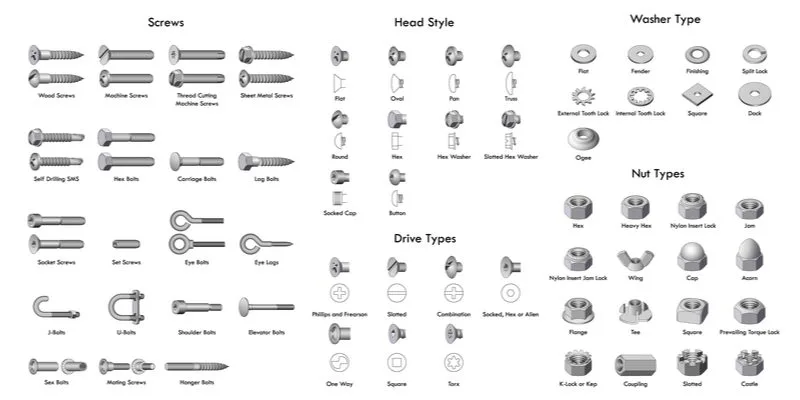

Incombile/Shutterstock

Now that you have a basic idea of where to look for differences, let’s work through some specific types of screws you’ll be likely to encounter.

1. Wood Screws

Kucher Serhii/Shutterstock

Wood screws, as the name implies, are best for connecting wood to wood. These screws are durable because they are most often made of brass or stainless steel material.

Wood screws are tapered, which means the spiraling thread section gradually gets smaller towards the tip. Wood screws can have flat or round heads, and the flat head type is particularly popular for drilling door hinges into the door frame.

Wood screws are durable, but they do have a downside—you need to drill the hole at three different sizes to properly hold them. For this reason, sheet metal screws have largely replaced wood screws.

2. Sheet Metal Screws

sacredmellor/Shutterstock

Sheet metal screws, as you probably suspect, attach pieces of sheet metal. Unlike the tapered shank of wood screws, sheet metal screws are straight up until the tip.

The holes in the metal are slightly smaller in size, which allows the wide threads of this screw to securely pull metals together.

Sheet metal screws have a weatherproof coating, and they usually have either flat heads, hexagonal heads, or round heads.

The main limitation of sheet metal screws is that the softer tip can’t work on thicker metals over 1/8th inch.

3. Machine Screws

Desizned/Shutterstock

You mainly use machine screws to hold parts of a machine together. As such, people use these screws frequently in the fields of electronics, engineering, and manufacturing.

Machine screws do not have a sharp tip, and they instead use a nut that pulls the two materials together.

For thicker metals, you must tap the hole and thread it before the machine screw goes in. These screws come in many different materials, depending on what you need.

4. Deck Screws

Do Mi Nic/Shutterstock

Decking screws can be a variety of lengths and widths, but they are sharp and tapered, which allows them to drive in at the speed of nails. Deck screws also have a coating material that resists corrosion.

Usually made of carbon steel, decking screws can attach wooden or composite boards to both wood and metal.

That is why they are ideal for decks—these screws attach the wooden or composite boards of a deck to the framing. Decking screws are also commonly used in fence building.

5. Hex Cap Screws

Alexsander Ovsyannikov/Shutterstock

Hex cap screws fall under the broader category of cap screws, which have large heads that are great for clamping material together. This clamping power makes them particularly useful for securely attaching machine parts.

The hex cap screws specifically have their name because of their hexagon-shaped head. They have a large diameter that resembles a bolt, and their steel threads provide a lot of strength. These screws also stretch slightly when drilled into place.

6. Drywall Screws

Deacons docs/Shutterstock

Drywall screws attach drywall material to wooden or metal studs. These screws have deeper threads that help prevent them from coming loose in the softer material of drywall. You will need to use a power screwdriver to securely fasten these screws.

Drywall screws come in two main varieties: coarse and fine. The coarse variety has wide threads and is best for gripping into wooden studs. And the fine drywall screws are double-threaded, making them ideal for drilling into metal studs.

7. Socket Head Screws

evkaz/Shutterstock

Socket head screws are a type of cap screw that has a hexagonal drive in the head. The hex head means that you need to use an Allen key or hex key to tighten these—a normal drill or screwdriver won’t work.

Socket head screws are sturdy, and they look beautiful because of how nicely they sink below the surface of the material you are drilling into. They are usually made of stainless steel, which gives them high corrosion resistance.

8. Weld Screws

Image/fastener-world.com

Weld screws attach to a metal surface without any holes because they are welded directly into place.

The tabs extending from the screw head provide a strong attachment after welding, and the shaft sticks out so that other parts can fit into place.

Because of this convenient shaft and the strongly welded attachment, these screws are ideal for engineering industries, especially the automotive, marine, and aerospace industries.

9. Framing Screws

Arturs Budkevics/Shutterstock

You use framing screws primarily to fasten different materials together in a non-structural way.

These screws work on a wide variety of materials, and the small teeth under the head of the screw allow it to nicely sink into these materials.

But an important note to make is that these screws aren’t strong enough for structural usage. They are great at fastening material together—like hardwood flooring—but it is crucial for safety that these screws not replace nails.

Frequently Asked Questions

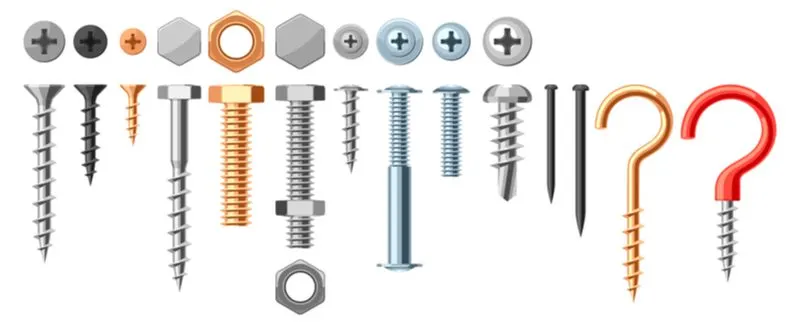

Shanvood/Shutterstock

Now that you’ve seen some of the most common screw types and when you should use them, let’s go over some of the most frequently asked questions on this topic that will clear up any remaining questions you might have.

What Are the Different Types of Screws?

The different types of screws reflect the differences in applications of screws. A screw can have unique qualities and measurements of drive, head, shank, threads, diameter, and tip. The differences in these components arose because engineers optimized them for specific usages.

And in addition to those screw parts, different types of screws are also made of various materials. Depending on the type, you can also coat screws in protective material as needed.

What Are the 3 Types of Screws?

As you saw in the above sampling of screw types, screws come in many varieties, each one optimized for specific situations. But like any classification system, you can break down screws into broader categories to understand the differences and similarities.

And screws have three main categories: machine screws, sheet metal screws, and cap screws. Machine screws are best for drilling into existing holes on metal surfaces.

Sheet metal screws have a sharp tip and sharp threads that allow them to cut into pieces of metal, wood, and many other materials. And cap screws, which have a large head, fasten machine parts to each other. The large head makes cap screws effective at clamping two materials together.

Why Are There Different Types of Screws?

The simple answer to why there are different screw types is that there is such a wide variety of constructing situations that use screws. Depending on the material and the equipment needed, screws have design parameters that optimize them for specific usage.

And in terms of the screw head, different types evolved to meet the demands of the various drilling methods.

A screw head that works best for a hand screwdriver isn’t the screw head that will work best with the high power and torque of a powered drill. The main drive for changing screw types over the years is to make construction more durable and efficient.

So, What Are the 9 Types of Screws?

Artfoto53/Shutterstock

Hopefully, you now have a much clearer idea of the different types of screws and the applications where you should use them.

While the list of screws does not cover every possible type you’ll encounter, these are among the most common varieties in use.